Unlocking Efficiency: The Role of Basket Type Rope Machines in Electrical Manufacturing

Release time:

2025-02-18

Basket type rope machines are essential tools in the electrical manufacturing landscape, significantly enhancing efficiency, product quality, and cost-effectiveness

1. Introduction to Basket Type Rope Machines

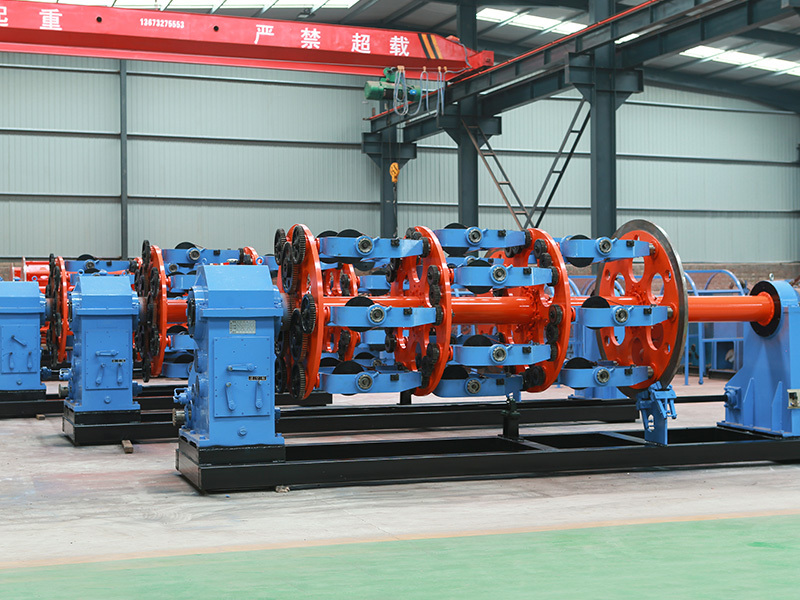

In the dynamic world of electrical manufacturing, efficiency and precision are paramount. **Basket type rope machines** have emerged as indispensable tools within this sector, revolutionizing how electrical components are produced. These machines, designed to handle various materials with ease, enable manufacturers to streamline operations while maintaining high standards of quality.

2. Understanding the Electrical Manufacturing Landscape

The electrical manufacturing industry encompasses a vast array of processes and products, from the simplest wires to complex electronic devices. As demand for high-quality electrical products continues to soar, manufacturers are continuously seeking innovative solutions to meet market needs. The integration of advanced machinery, such as **basket type rope machines**, plays a vital role in enhancing productivity and reducing production time.

3. Key Features of Basket Type Rope Machines

Basket type rope machines are characterized by several features that set them apart from traditional manufacturing equipment. Some of the key attributes include:

- **Versatility:** These machines can handle a wide range of materials, making them suitable for various applications in the electrical manufacturing process.

- **Automation:** Many basket type rope machines come equipped with automated features, reducing the need for manual intervention and minimizing the risk of errors.

- **Precision Engineering:** These machines are designed to provide precise control over the manufacturing process, resulting in high-quality outputs.

4. The Benefits of Using Basket Type Rope Machines in Manufacturing

Investing in basket type rope machines can yield significant advantages for electrical manufacturers. Below, we delve into some of the most compelling benefits.

4.1 Enhanced Operational Efficiency

One of the most notable advantages of implementing basket type rope machines is the dramatic increase in operational efficiency. By automating various processes, manufacturers can produce electrical components faster while ensuring that each stage of production adheres to high-quality standards. This efficiency translates to reduced lead times and improved production schedules.

4.2 Cost-Effectiveness and Resource Optimization

Basket type rope machines are designed to optimize resource utilization. By minimizing waste and maximizing output, these machines contribute to overall cost savings. Additionally, their efficient operation can lead to lower labor costs as fewer operators are needed to manage the production line.

4.3 Improved Product Quality and Consistency

Quality is a critical concern in electrical manufacturing. Basket type rope machines provide consistent results, ensuring that each product meets specific quality standards. The precision offered by these machines reduces the likelihood of defects, resulting in higher customer satisfaction and fewer returns.

5. Integration of Basket Type Rope Machines into Existing Systems

Successfully integrating basket type rope machines into existing manufacturing processes requires careful planning and execution. Here’s how to ensure a smooth transition.

5.1 Compatibility with Other Manufacturing Equipment

Before introducing basket type rope machines, manufacturers should assess their current equipment to determine compatibility. Many modern machines are designed to work seamlessly with other industrial tools, thus facilitating a smoother integration process.

5.2 Training and Adaptation for Operators

Human capital plays a significant role in the successful implementation of new machinery. Providing comprehensive training for operators will ensure they are well-equipped to handle the machines effectively. This training should cover both operational procedures and safety protocols to maximize productivity and minimize accidents.

6. Case Studies: Successful Implementation of Basket Type Rope Machines

Real-world examples can illustrate the transformative effects of basket type rope machines in electrical manufacturing. Companies that have adopted this technology report significant improvements in their production processes:

- **Case Study 1:** A leading electrical components manufacturer integrated basket type rope machines into its production line, resulting in a 30% reduction in lead time and a notable enhancement in product quality.

- **Case Study 2:** Another organization experienced a 25% decrease in production costs after implementing these machines, attributed to reduced waste and optimized resource use.

7. Future Trends in Electrical Manufacturing and Rope Machines

The electrical manufacturing industry is ever-evolving, with technological advancements shaping how products are made. As we move forward, we can expect the following trends concerning basket type rope machines:

- **Increased Automation:** The trend towards automation will continue, with more manufacturers adopting advanced robotic systems to work alongside basket type rope machines.

- **Sustainability Focus:** As manufacturers prioritize sustainability, basket type rope machines that minimize waste and optimize energy use will become increasingly popular.

- **Smart Manufacturing:** The integration of IoT (Internet of Things) technology will enable real-time monitoring of manufacturing processes, enhancing the efficiency of basket type rope machines.

Basket type rope machines are essential tools in the electrical manufacturing landscape, significantly enhancing efficiency, product quality, and cost-effectiveness. As the industry continues to evolve, manufacturers that adopt these advanced machines will position themselves for long-term success. By embracing innovation and optimizing processes, companies can unlock new levels of productivity, ultimately leading to greater customer satisfaction and improved market competitiveness.

Recommend News

HEXING CABLE MACHINERY

TEL: +86-317-3601666, +86-317-3236119

FAX: +86-317-3618408

E-MAIL: china@hbhxdg.cn

E-MAIL: hbhxdg@gmail.com

WEB: http://www.hbhxdg.cn

ADD: Baoantun Industrial Zone, Hejian City, Hebei Province